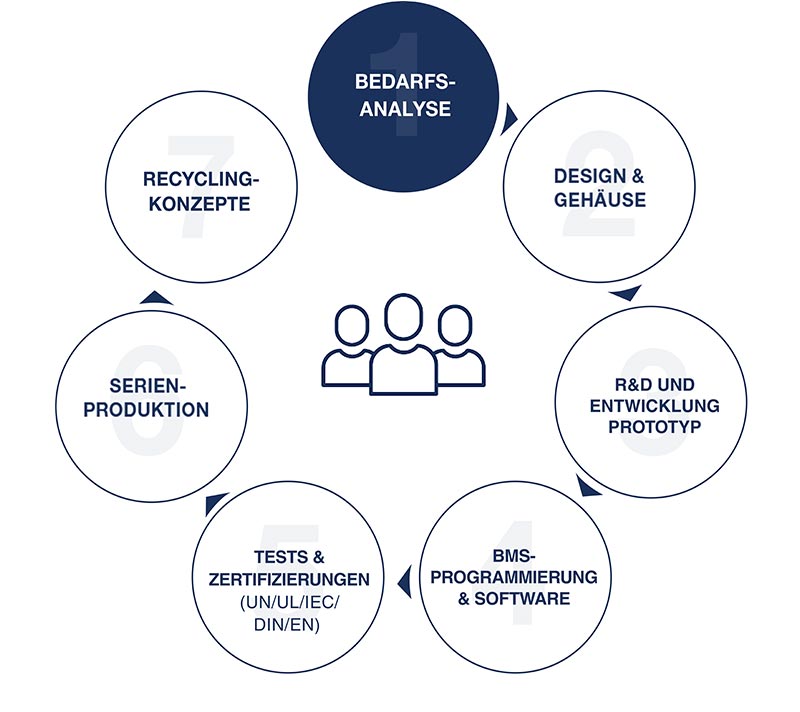

We analyse your technical requirements and find the solution that best meets your demands. We determine the parameters required for your battery pack:

- electrical (e.g. voltage, capacity, resistance, operating and charging currents)

- mechanical (e.g. size, weight, mechanical stresses) and

- electronic (e.g. related to the electronic monitoring system)