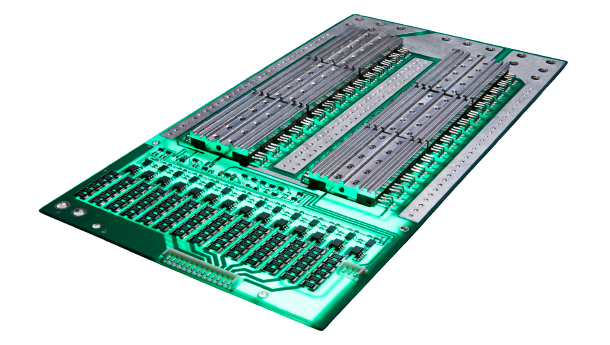

Service overview

From the electronics to the sophisticated design, we develop customised Li-ion and nickel metal hydride battery packs for a wide range of markets and requirements. Our development department employs a team of highly qualified engineers. In addition to the battery cell experts, we also employ

- Design engineers

- Hardware and software developers

- Test engineers and prototype technicians

- Specialists in welding technology

- Specialists in thermal management, charging technology and many other innovative topics